Pressure vessels are a big group of tanks that can be used in many industries and for many processes. What is common for all pressure vessels is that they are able to withstand pressure. A tank becomes a pressure vessel when it is able to withstand a pressure higher than 0.5 bar grams of pressure.

JH Stålindustri produces pressure vessels where every single detail is thought through and documented according to the current legislation and standards.

The Many Uses of Pressure Vessels

Pressure vessels are the preferred tanks for processing lines in many industries. For instance, pressure vessels are used in:

- The dairy industry

- The food industry

- The chemical industry

- The pharmaceutical industry

Pressure vessels are used, among other things, as mixing tanks, for fermentation, flashing, high pressure boiling, pressurised fluids, aseptic, gas storage or as buffer tanks.

Usually pressure vessels are used as indoor tanks, but we can also easily produce tanks that can be used outside. Furthermore, pressure vessels are often used in closed systems and production lines.

Sterile Pressure Vessels

Is there a part of your process that needs to be sterile? Is so, a pressure vessel is probably the right choice for this process line. The big advantage of pressure vessels is that you can completely avoid external influences. To do so, a sterile tank must always be tightly closed.

For example, in the pharmaceutical industry sterile water is used frequently. When the water has been made sterile, it is kept sterile through the rest of the process by staying in a pressure vessel. A sterile pressure vessel will always keep the content of it sterile due to its pressure.

UHT plants are another good example from the dairy industry in which food is being heat treated/pasteurized at temperatures up to 140 degrees. After that it is crucial that the food is kept clean if it is going to be sold. That is why pressure vessels are so important, because they can mitigate all external influence and keep their contents clean.

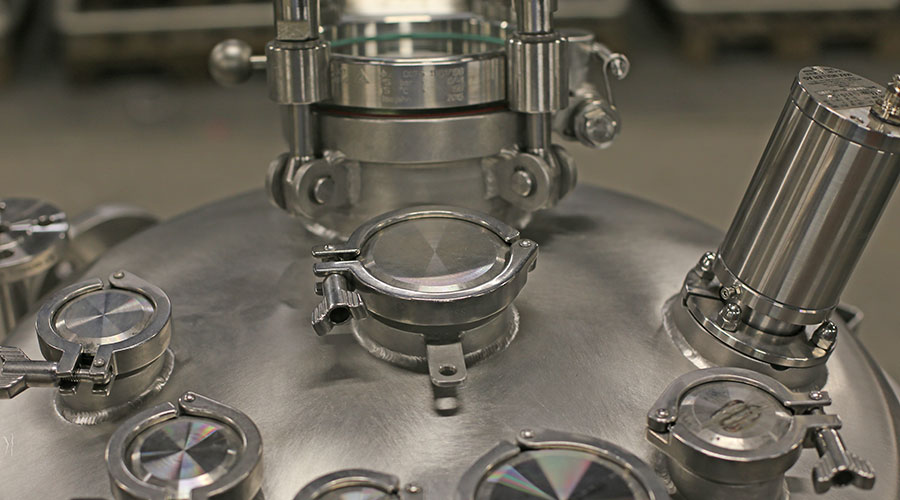

We Manufacture Premium Stainless-Steel Pressure Vessels

At JH Stålindustri we manufacture stainless-steel pressure vessels according to the demands and specifications of our customers. We place a high importance on the European standard EN 13445 which is the EU standard for the construction of pressure vessels. When we manufacture a pressure vessel it will always involve:

- An open dialogue with our customers to understand their needs and specifications

- Precise calculations and blueprints from our engineers

- Precise craftmanship from our welders

- Complete documentation of the whole manufacturing process and a full traceability on all materials

Our Importance with Customer Dialogue

When we manufacture a pressure vessel, it is important that we have 100% understanding of how the pressure vessel will be used in your production line. That is why we have constant and open dialogue with our customers, so we can ensure that the right specifications are met. We may ask questions related to the following:

- Mounting: depending on the dimensions and the volume of the tank, it can be placed on round or triangle conical legs or hanging in consoles

- Insulation: if the tank will be used where process temperatures are either high or low, it will be necessary to insulate the tank. The insulation cloak can be fully welded using stainless-steel when the bacteriologic standards are high. Alternatively, a riveted aluminum plate will be used when thinking more economically. We of course inform and calculate the right kind of insulation and the right insulation thickness

- Requirements for cleanliness: sterile tanks and pressure vessels in which there is an importance placed on cleanliness will have a special focus on surface requirements and ability to drain.

These are just some of the topics we may discuss with customers in the planning phase.

JH Stålindustri Is a Trusted Industry Leader

At JH Stålindustri we take pride in a high level of customer service. That is why our customers have high expectations to our work. Our process involves:

- A thorough and in-depth dialogue between us and the client to make sure we are 100% aware of the customer’s needs and requirements for the tank

- Full traceability on all materials

- Making sure the customer understands all the technical details about the tanks. As an example, we use 3D drawings and models to educate customers.

- Documentation for the manufacturing of the tanks. Among this documentation will be welding certificates and tests on surface, pressure, drainage and much more

If you have any questions, our knowledge about the processes used in different industries will be extremely helpful.

Contact JH Stålindustri today if you want to know more about our stainless-steel pressure vessels or our procedures. We can be reached via the telephone at +45 86 47 90 44 or by e-mailing us at jhstaal@jhstaal.com