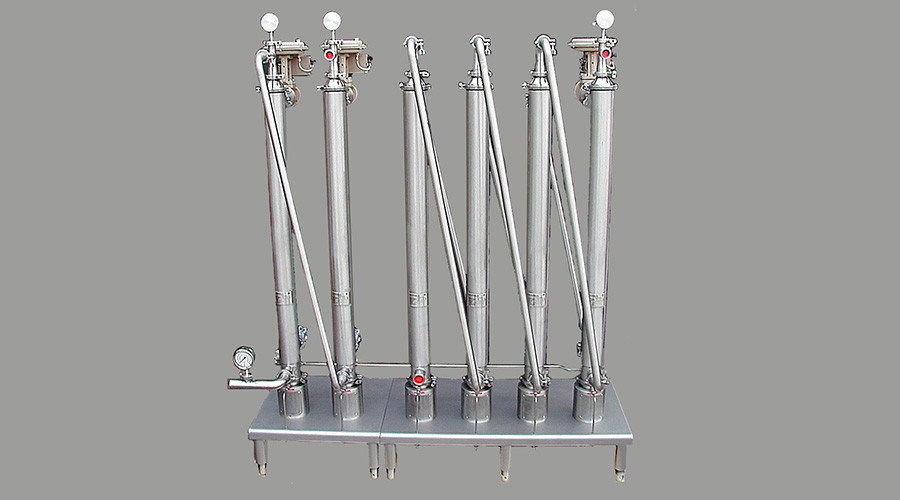

JH Stålindustri is one of the best in the industry when it comes to the custom designs and the production of our stainless-steel scraped surface heat exchangers. In fact, we have even come up with our own creation known as Rotapro. Rotapro is used for heating and/or cooling of high viscosity products that contain objects such as berries, nuts, and other small items up to 30 mm in size.

Our scraper heat exchanger is used across industries. It is used in:

- The food industry

- The dairy industry

- The chemical industry

- The pharmaceutical

- The cosmetic industry

- The fishing industry

The Rotapro Scraped Surface Heat Exchanger is the Reliable Choice

The Rotapro scraped surface heat exchanger is our signature product and is a result of many years of experience in the industry. At JH Stålindustri we have specialized in the development of high-quality stainless-steel products since 1990. We have taken this experience to come up with something revolutionary.

Our employees are dedicated to their work and take pride in delivering an excellent piece of Danish craftsmanship. At JH Stålindustri we are proud to be known as being able to produce the most efficient and the most reliable scraped surface heat exchangers on the market.

The Right Solution for High Viscosity Products

If your production line products need heating or cooling, it can be a complicated process, especially when you are working with high viscosity products. Often, the structure of these products can result in contamination of the production equipment. That is exactly why we created the Rotapro. The Rotapro scraped surface heat exchanger is developed to avoid contaminating and will provide the optimal temperature for any product.

The Efficient and Reliable Heat Exchange Process of the Rotapro

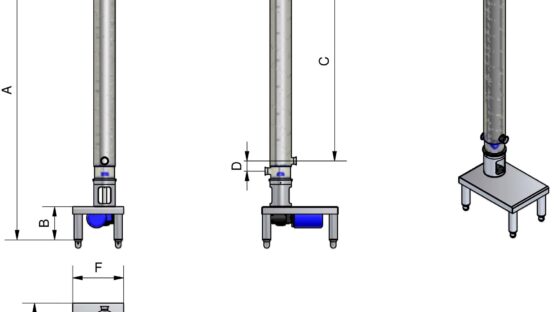

When you use the Rotapro scraped surface heat exchanger, the product enters in the bottom of the cylinder and is brought upwards. As it rises, air is flowing in the opposite direction of the product and provides cooling, or heating, as the product flows through a narrow channel. This air flow ensures that the product’s temperature is kept at an optimal level, and that the heat exchange is this running consistently.

To keep the product safe, it will flow in the same direction as the rotation of the scraping blades inside the tank.

The Rotapro scraped surface heat exchanger is a reliable and efficient solution that guarantees full control over the heat exchange process.

Scraper heat exchanger designed for efficiency

The design of the Rotapro scraped surface heat exchanger makes it ideal for the manufacturing of many different products. In fact, it is used in many different areas due to its flexibility. Most commonly though, it is found in the food industry. It is vital in the production of:

Here it is used i.a. to:

- Sauces

- Spices

- Soups

- Dairy products

- Fruit based products

- Processed meat

- Ready meals

- Confection

- Baby food

The Rotapro Scraped Surface Heat Exchanger Provides Aseptic Treatment of Food Products

The Rotapro is a scraped surface heat exchanger that is commonly used for the aseptic treatment of high moisture food products. These food products are classified in 4 categories from B, C, D to E on a basis of their viscosity which is measured in cP (centipoise)

The Rotapro scraped surface heat exchanger can provide aseptic treatment of temperatures up to 145 degrees Celsius.

The Working Processes of the Scraped Surface Heat Exchanger

The Rotapro scraped surface heat exchanger can be a part of many different production processes. These production processes are mainly related to heating and cooling of products with high viscosity, but Rotapro has the extra advantage of being able to help with mixing and combining of the product.

High viscosity – The plate or tube-shaped heat exchangers can be used for heating or cooling. But when it comes to products with high viscosity (above app. 800 cP) or big particles, a scraped surface heat exchanger is necessary. Rotapro is the most reliable way to efficiently heat and cool a high viscosity product through its process of using a low loss of pressure to reduce fouling.

Heating – Rotapro makes a precise heating treatment of any product possible. The Rotapro ensures that all the specific requirements are met for the product. That is why Rotapro can safely be used to for the pasteurization and sterilization of products.

Cooling – Rotapro can be used as an efficient way to cool the product before the packaging process begins. For example, Rotapro is used before packaging warm products in plastic containers by quickly cooling the product beforehand.

Crystallization – Rotapro can be used in the crystallization process. The continuous movement of the scraping blades efficiently helps to move and crystallize the sticky product through the cylinder.

Caramelization – Rotapro is also efficient in the process of browning and melting sugar. The custom designed scraping blades works around the clock to make sure that the product is easily pushed through the cylinder.

Advantages of Using a Rotapro Scraped Surface Heat Exchanger

When it comes to upgrading your production facilities it takes a lot more than just the purchase of new processing equipment. It is more important to find the right partner who can create a solution that will add value to your production line for years to come.

As a result, choosing a supplier is not just about the price and delivery time. It is also about identifying the right people to work with. That is where we come into play. At JH Stålindustri you will be working with a group of enthusiastic and dedicated employees with many years of experience that love to solve problems. Our staff provides the following for all our customers:

- Reliable and certified Danish craftmanship

- A supplier that specializes in developing flexible solutions to meet the specific needs of every customer

- A supplier with many years of know-how that is easily accessible and quick to provide an expert guidance

- A solution in which all aspects, from the technical to the practical aspects, have been carefully thought through

- A simple solution that works immediately, with a focus on efficiency, production speed, on time delivery, and no extra costs

- A solution that lasts for a long time and requires minimum maintenance

- The ability to get high quality materials for a low price

All these advantages allow us to offer the most cost-competitive prices on the market!