Our stainless-steel storage tanks are mostly used outdoors for storage of raw materials. These tanks can be used in connection to a treatment program or in a production line. JH Stålindustri produces some of the finest stainless-steel storage tanks in the industry. This is a result of our focus on using high quality materials. In fact, we document all of our materials and send it to you, so you know what your storage tanks are made of!

The Use of Storage Tanks

Stainless-steel storage tanks are used in many different industries. Most commonly though, they are found in the pharmaceutical industry and the dairy industry. This is because these storage tanks provide an option for constant ventilation to avoid over-pressure or under-pressure. In these industries, you will find the tanks being used for:

- Fermentation tanks

- Growth tanks

- Buffer tanks

When it comes to finding a storage tank that fits your needs, it is time to contact us. At JH Stålindustri we custom manufacture stainless-steel storage tanks to meet your needs. From the products used, to the design, and the size (up to 150 cubic meters), we have the solution for you. If you need any help along the way, our experts are waiting to answer any questions you may have.

How We Manufacture Stainless-Steel Storage Tanks

We manufacture stainless-steel storage tanks according to our customers’ specific requirements for their unique specifications. As a result, our customers are always happy and have a tank that fits in perfectly with their specific production line. When you order a storage tank at JH Stålindustri our manufacturing process does not just include making it. We go through the following steps for our customers:

- Open dialogue with our customers about their specifications and environment

- Precise calculations and plans from our engineers

- Precise craftmanship from our welders

- Thorough documentation of the whole manufacturing process and full traceability on all materials used.

We are Ready to Meet Any Customer’s Requirements

JH Stålindustri is an industry leader for a reason. We have the capabilities to create tanks with

unique specifications according to our customers’ needs. For instance, storage tanks can be customized to include:

- Test tap

- Agitator which is either top mounted or side mounted

- Watching glass with light

- Instrument connection for pressure, temperature, and level measurer

- Safety railing

- Under and over pressure safeguard

- Overflow safeguard

- Template to change or keep the product’s temperature

- Walkway with safety railings on the top for easy access between several storage tanks

- Mounting and installation of storage tanks

Through dialogue with our costumers we can find the exact needs and start our preparation phase. As a result, our clients have a clear idea of the time, cost, and design of their storage tanks.

Insulation of Stainless-Steel Storage Tanks

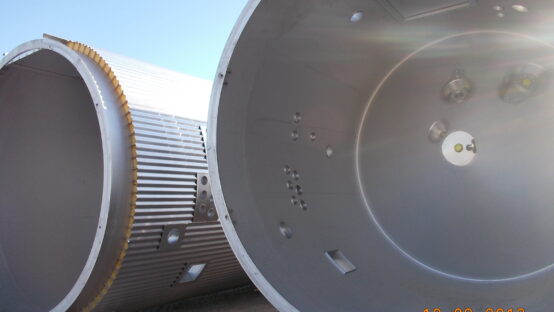

Outdoor storage tanks are mostly insulated with Rockwool. There are different options when it comes to the design of the insulation cladding. We are happy to help when it comes to finding the best way to provide insulation cladding for a specific tank. Here are some general ways we do this:

- The insulation cladding on the top of the tank can either be of aluminum or as a fully welded stainless-steel plate that has been painted with non-slip painting

- The insulation cladding on the casing is often trapezium or sine shaped painted aluminum plates

JH Stålindustri Is the Go-to Brand for Storage Tanks

At JH Stålindustri we understand that the quality of stainless-steel tanks for a processing line is crucial for the quality of the final product. That is why we take pride in providing the highest quality tanks in the business. When working with our team, our customers can expect:

- That we make sure we are 100% aware of the customer’s needs and requirements for the tank

- A constant effort is made to make sure the customer understands all the technical details about the tanks. We may provide 3d diagrams to give a visual cue.

- Documentation for the manufacturing of the tanks. Among this material will be welding certificates, surface checks, pressure checks, drain tests and much more.

Work with the Best Welders in The Business

To manufacture premium storage tanks using stainless-steel is a craft that few have mastered. Luckily, our welders are among this select few and possess a drive to deliver excellence. Our craftsmen are all certified in accordance with the PED requirements and can work with:

- Different materials

- Different welding methods

- Different goods thickness

The certifications are only valid for 3 years, and therefore we can guarantee that our blacksmiths are always fully updated with the latest knowledge and the latest methods.

Contact JH Stålindustri today if you want to know more about our stainless-steel storage tanks or our procedures. We can be reached via the telephone at +45 86 47 90 44 or by e-mailing us at jhstaal@jhstaal.com